A realistically scaled ventilation training unit capable of enabling students to study both basic airflow and fluid mechanics as well as the more complex process of commissioning and balancing a multi-ducted air distribution system.

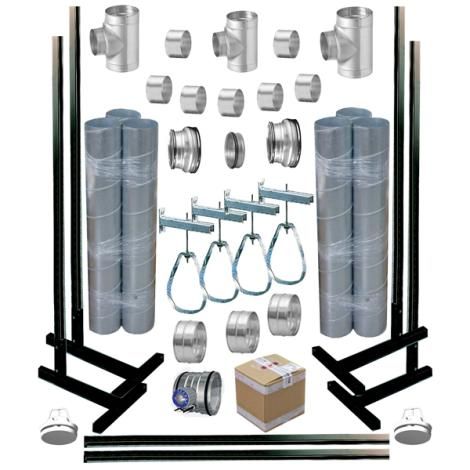

The unit consists of a foreword curved variable speed centrifugal fan and integral control console together with a rectangular air intake and filter holder. The fan has a supply pressure of up to 890N/m2 and a flow rate of up to 0.8m3/s depending upon the blockage factor. The fan discharges directly into a 200mm dia. galvanised steel duct and this connects directly to the distribution ductwork.

Sufficient components are supplied with the unit to enable parallel branch and line balancing experiments to be undertaken. A minimum of 6 air supply points are provided that may be balanced on the assembled unit to supply a range of airflows. A portable manometer, pitot static tube and hand held anemometer allow a large range of experiments to be undertaken.