With all industry sectors under immense pressure to significantly reduce carbon emissions by 2050 — in line with the Government’s carbon budget — every aspect of the engineering process is being looked at to ascertain best practice for moving forward in a sustainable way. Benefitting business is still important, and the burden is in the balance; how to find ways to sustain business in an environmentally conscious way adds an extra challenge to the next generation of green engineers, who will need to ponder not only best business practices but also green business practices.

Green engineering is already commonplace; we barely notice an ‘eco-build’ when we stroll past it, such is their popularity. Our coffee cups are sustainable. People drive past us in electric cars, which are becoming ever more popular; according to the Society of Motor Manufacturers and Traders (SMMT), electric car sales increased by more than 350% from 2017-2018. The UK’s already seemingly daunting 2050 target of reducing 1990 carbon emissions by a staggering 80% has now become even more so, with the Prime Minister proposing we, as a nation, aim to be emitting close to zero greenhouse gas emissions by that time[1]

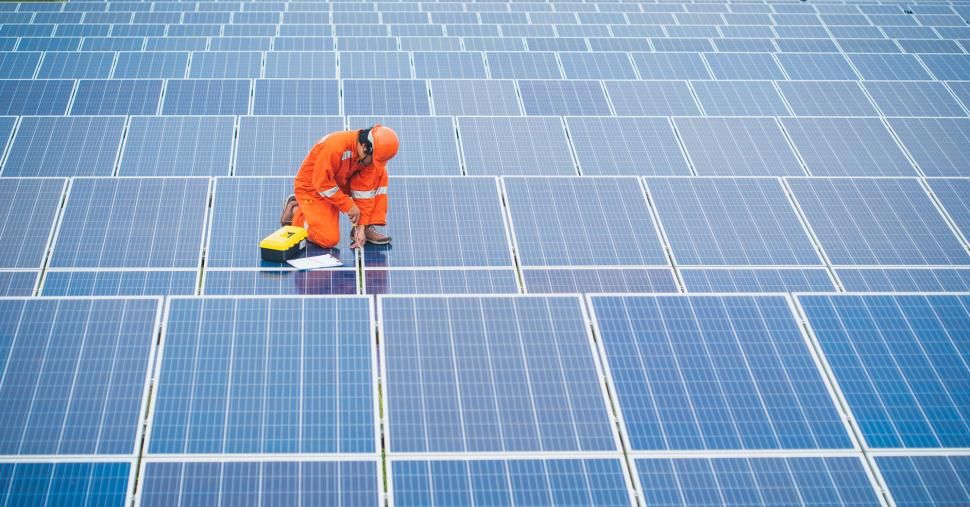

To keep up with and contribute towards this target engineering needs to be amended at every step of the way, from conception to completion, with a green focus not only on materials and carbon footprint reduction, but also waste elimination and energy efficiency. Businesses within the engineering industry are making changes, some already considering ecologically viable working practices. The most obvious starting pointing is that of energy: the force behind any business. Certainly, the first step towards truly green living and working is in ensuring that all energy used is green and derived from renewable sources.

When the term ‘carbon budget’ was first thrown about, a struggle was identified: how could a business develop and grow if fettered by an issue as enormous and vital as that of the future health of the planet? The answer is simple — adapt and survive. One small innovative step for engineering could well be one giant leap for mankind, with the overriding principle being that of alternatives. Consider aeroplane engines — for years they ran reliably on gas turbine jet engines, with few people batting an eyelid at the wider impact of such a fuel-hungry means of travel, and those who did dismissed as overly cautious. But we now all know that emissions have to drop, noise needs to reduce, fuel consumption has to decrease, and this leaves us with no choice other than finding alternatives.

Completely reinventing the wheel, or indeed the engine, could be some way off, although the first ‘solid state plane’ with no moving parts successfully took flight in November 2018, flying for a distance of 60 metres[2] and paving the path for a future in which travel could be completely carbon neutral. In the interim, smaller steps must be taken along this path; fuel efficiency can be improved, with biofuel options gradually being adopted by many commercial airlines. Using alternative materials for components is also an engineering challenge, and one that will reduce fuel consumption, saving hundreds of kilograms of CO2 on each journey an aeroplane makes.

So what does the future hold for the environmentally conscious engineer? Traditionally, being environmentally conscious meant a focus on the health and wellbeing of people and the prosperity of society, anchored on quality of life. The paradigm shift into looking after our planet as well as ourselves presents a more holistic challenge with engineers having to consider numerous delicate facets and how to balance them. A continuing focus on the design of innovative eco-aware technologies is paramount: easily accessible sustainable materials negate the need for quick-fix less eco-friendly options. Ensuring wind power, solar power and carbon-neutral heating systems are the norm will reduce the engineering industry’s phenomenal use of resources, and finding a viable means of offsetting when it’s just not possible to opt for a zero-waste process or material complete the eco-triangle.

Forward-thinking will be key, and problem-solving will need to consider not only a local solution but one that reduces global impact. Every step and aspect of a process should be considered and scrutinised, from design to transportation and manufacture. Not only is this key to a healthy planet but also a healthy industry; tomorrow’s consumers are likely to choose only to do business with environmentally conscious engineers aware of the impact of their footprint on our planet.